Services

Woodsol's

23rd Anniversary

We make water do what you want

Boiler Water Treatment

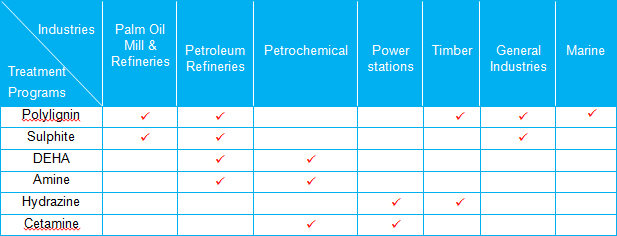

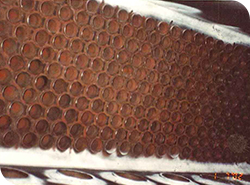

Despite careful external treatment of feed water for boilers, it is imperative to use certain chemicals to control corrosion, scaling and carry-over in boilers. The use of our products maintains boiler water at intended parameters and withstanding significant changes in the water condition. WOODSOL prides in tailor made solutions, supplying various types of organic and inorganic treatment programs.

POLYLIGNIN PROGRAM : Palm Oil Mills & General Industries

WOODSOL’s signature mode of boiler water treatment for Palm Oil Mills & refineries, Petroleum refineries, Timber & General industry and in Marine as well. We highly recommend this mode of treatment because it consists of an organic product that is not detrimental to the environment. We are firm believers of nature conservation and the polylignin boiler water treatment plan delivers just that! It is a perfect combination of tannins, lignins, seaweed extract and sodium lignosulfonate. These FDA approved-compounds have oxygen scavenging, scale modifying and metal passivation characteristics that will ultimately result in a clean boiler. What is more interesting is that, this program does not significantly increase the Total Dissolved Solids which will save you inventory costs.

SULPHITE PROGRAM : Palm Oil Mills & General Industries

SULPHITE PROGRAM : Palm Oil Mills & General Industries

An excellent oxygen scavenger, sulphite in the form of catalysed sulphite reacts with oxygen and controls the oxygen levels in the boiler water. There is no passivation action with this treatment and corrosion in the boiler is controlled solely on the ability of removing oxygen from water. However, there will be an increase in TDS as the boiler pressure increases if there is no deaerator or if the feed water temperature is low. Therefore, the use of sulphite treatment is limited to low and medium pressured boilers.

DEHA PROGRAM : Petrochemical Industries & Refineries

WOODSOL’s N,N-diethylhydroxylamine (DEHA) based products has exceptional oxygen removal properties and passivates boiler metal surface. A total control of corrosion is achieved by increasing the pH of the water to allow neutralisation of acids.

AMINE PROGRAM : Petrochemical Industries & Refineries

The product consists of high alkaline chemicals that will neutralize the carbonic acid formed upon condensation. Oxygen in the water is kept less reactive by maintaining alkaline conditions in the boiler.

HYDRAZINE PROGRAM : Power Stations & Timber Industries

HYDRAZINE PROGRAM : Power Stations & Timber Industries

Our hydrazine-based product is a good oxygen scavenger and corrosion inhibitor. A closed feed system will be needed as over exposure is not recommended. Hydrazine treatment is suitable for power stations and timber industries where the steam or water is not directly exposed to food and beverages due to its highly toxic nature.

CETAMINE PROGRAM : Petrochemical & Power Stations

CETAMINE PROGRAM : Petrochemical & Power Stations

This treatment is based on a filming effect that is done by the polyamine present. It is particularly a recommended mode of treatment for industries that have condensate return lines. The thin film is adsorbed onto metal surfaces and functions as a continuous barrier between oxygen in the water and the metal. The amine also helps maintain the pH of the condensate water through its neutralizing action while other amines function to disperse scale-forming salts.